Leading material for water tank construction due to its

superior strength, durability, and resistance to corrosion

Our Product

GRP Water Tank

Home

About Us

Products

Technology

Contact

© Copyrights 2024.Kunyi Panel Tank Sdn Bhd.All Rights Reserved.

011-5553 9982

No. 196, Batu 9, Jalan Kapar, 42200 Kapar, Selangor

KPTSB@kunyimalaysia.com.my

03-3250 3613

Introduction

What Is GRP?

Glass Reinforced Plastic (GRP), also known as fiberglass (FRP), has emerged as a leading material

for water tank construction due to its superior strength, durability, and resistance to corrosion.

Advanced GRP panel technology enhances the efficiency, sustainability, and performance of

water storage systems.

Material Composition:

GRP panels are made by combining glass

fibers with a polymer matrix, typically

unsaturated polyester resin. This combination

results in a lightweight yet robust structure.

Modular Design:

Panels are designed to be prefabricated

and modular, allowing for easy transport

and quick assembly on-site. This reduces

construction time and labor costs.

Corrosion Resistance:

GRP panels are inherently resistant to

corrosion, making them suitable for storing

potable water and other liquids. This

characteristic extends the lifespan of the

tanks significantly.

Thermal Insulation:

The material provides excellent thermal

insulation, minimizing temperature

fluctuations in stored water, which is crucial

for maintaining water quality.

Customisability:

Panels can be manufactured in various

sizes and thicknesses, allowing for

customization based on specific project

requirements and space constraints.

KUNYI PANEL TANK (M) SDN BHD

(1290997-W)

© Copyrights 2024.Kunyi Panel Tank Sdn Bhd.All Rights Reserved.

011-5553 9982

No. 196, Batu 9, Jalan Kapar, 42200 Kapar, Selangor

KPTSB@kunyimalaysia.com.my

03-3250 3613

Corporate

Sales Enquiry: 03-3250 3613

Email: KPTSB@kunyimalaysia.com.my

- Product

- Projects

Production

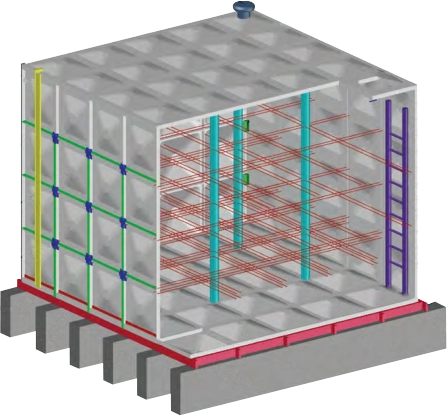

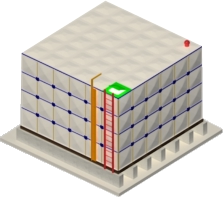

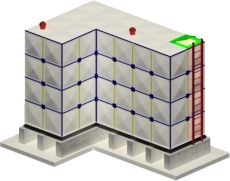

GRP Water Tank Details

Advanced GRP Panel Technology

Our GRP water tanks are manufactured with advanced hot press technology using premium Sheet Moulding Compound

(SMC). This method ensures that every tank is lightweight, corrosion-resistant, and with an option of insulated panels,

making it ideal for storing potable water and other liquids.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1.

Air Vent

2.

Internal Corner Bracket

3.

Manhole

4.

External Ladder

5.

Internal Ladder

6. Skid Base

7. Tie Rod

8. Roof Pole

9. Bottom Panel

10. Drain/Scour

11. Concrete Plinth

12. Flat Bar

13. Body Angle

14. Stay Plate

15. Side Panel

16. Corner Angle

17. Water Level Indicator

18. Top Panel

GRP Panel Composition By Height

Advanced GRP Panel Technology

Meter

1

1.5

2

2.5

1

1.5

2

2.5

3

3.5

4

3

3.5

4

4.5

5

4.5

5

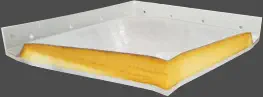

KUNYI Preinsulated Side Panel and KUNYI

Preinsulated Side Panel Cut Piece

Preinsulated Panel with

> GRP Skin 2mm thickness

> PU Foam 40mm

> Panel size 1.0m x 1.0m, 1.0m x 0.5m

POLYURETHANE INSULATION LAYER

* Specification for Glass Reinforced Polyester sectional water tanks SS 245: 2014

•

Depth (D) of GRP sectional water tanks shall be not exceeding 4m

•

Depth (D) which exceeding 4m shall be of manufacturing design

GRP Panel Thermal Conductivity

Thermal Conduction Kcal/mhr

o

C

Insulation Type

Single Layer Type

Tank Type

Steel, STS

37

37

GRP Tank

0.15 (over 370 times)

0.017

Definition

Physical Properties

Tensile Strengh

99.5 MPa

Bending Strengh

165 MPa

Elastic Modules in Band

13800 MPa

Glass Fiber Ratio

30% dan fazla

Barcol Hardness

30 dan fazla

Water Absorption Rate

0.01%

Water Temperature

It can be used up to 50

o

C

Advanced GRP panel technology represents a significant advancement in water tank

design and construction. With benefits such as corrosion resistance, lightweight

properties, and high customization potential, GRP panels are a versatile and sustainable

choice for various water storage applications.

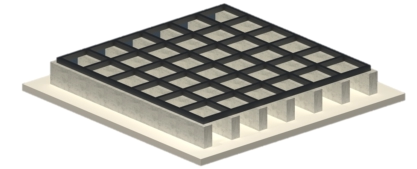

To mount GRP (Glass Reinforced Polyester)

storage tanks securely, they're generally

fixed onto an outer flange, necessitating a

robust steel base frame over a dedicated

concrete pad. This steel base ensures that

the tanks base panels are fully supported,

offering a more rigid and stable structure.

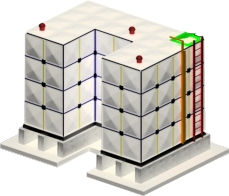

Tank Application Combinations

Standard

Type

U Shape

Type

C/C 1Meter

Concrete Plinth

Skid Base

GRP Steel Skid Base

L Shape

Type

Characteristics Of Hot-Press GRP / Water Tanks

HYGIENE

The smooth gloss finish ensures

high resistance to debris

attachment, maintaining

superior cleanliness over time.

CONTAMINATION OF WATER

Tank panels made using HOT-

PRESS TECHNOLOGY ensure water

remains free from any impact on

taste or smell.

WATER TIGHTNESS

Foam sealants resist oxidation,

weathering, fungus, and water

absorption, ensuring a long-

lasting seal.

RESISTANCE TO CORROSION

AND DETERIORATION

The smooth surface minimizes

debris attachment, offering

enhanced long-term durability

and resistance.

TANK WEIGHT

The lighter tank assembly uses

stronger panels and optimized

design, requiring fewer external

reinforcements.

EASE OF MAINTENANCE

Corrosion-resistant stainless

steel components (bolts, nuts,

and washers) simplify and

reduce maintenance needs.